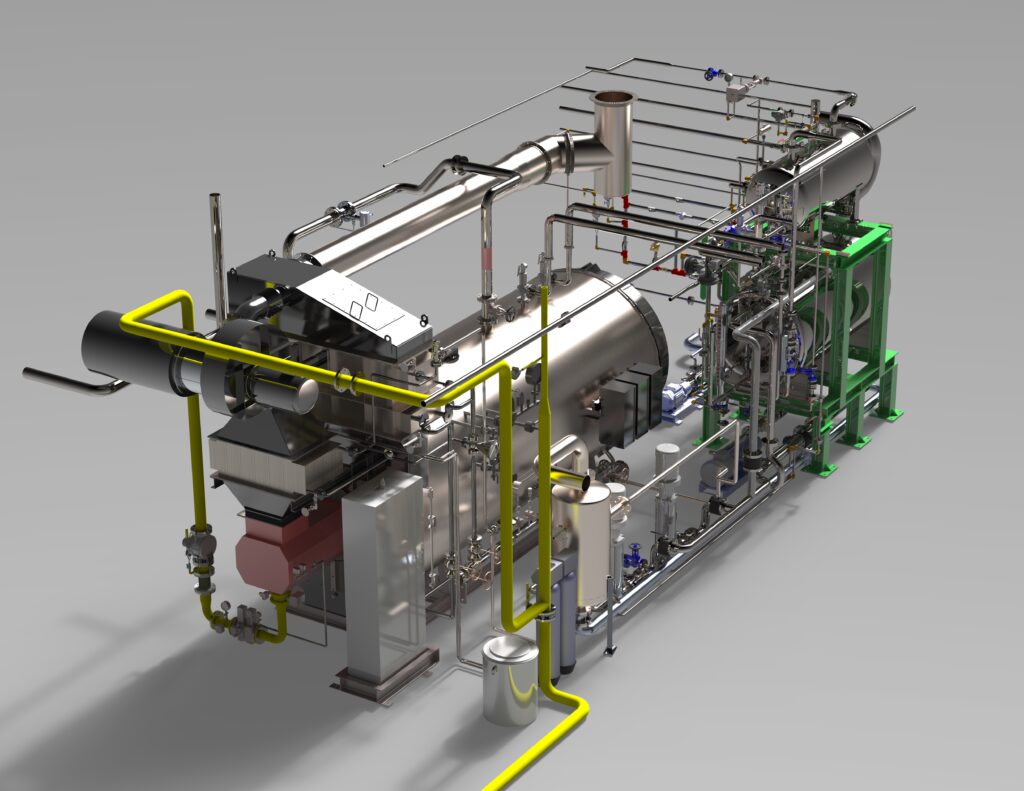

Mevas supply a complete boiler room at cartiera SAN GIORGIO with the new Tower Eco System Injection. Based on years of experience and collaborations with the largest boiler manufacturers, Mevas has developed TESI (Tower Eco System Injection). TESI can be adapted to any type of condensate return system for new generation boilers, with very low layout impacts and reduced installation costs thanks to its positioning on a skid with a support structure certified according to EN 1090.

TESI is equipped with an independent control PLC able to manage all the operating phases separately from the boiler logic, in order to reduce the commissioning times, manage the transitory and warm-up phases, favoring a better diagnosis of the process. The PLC is equipped with a system for remote assistance, provided in order to monitor the process and maximize the speed of intervention in case of requests from the customer. All system automation is perfectly integrated with the boiler PLC and the customer DCS.

The real revolution of the TESI system lies in the new plant engineering approach with which the thermal power plant is seen; if until now the only pre-assembled component was the boiler, now also the condensate recovery and the thermophysical treatment of the feed water will benefit from the rapid installation typical of compact systems.

The versatility of TESI is such that it can allow, through the addition of the Sp package (Steam Pack), the exploitation of enthalpy flows coming from a primary process (for example hot fumes extracted from the paper process, exhaust gases from turbogas etc. ) acting as a real recovery boiler.

The TESISp package (Steam Pack) therefore allows steam production at different pressure levels (TESISpL for steam up to 9 bar and TESISpH for steam up to 20 bar), considerably increasing the overall efficiency of the steam production plant. , minimizing the impact on the overall layout.

The combination of HE Smart and TESI technologies allows you to manage the production process with its steam requests and the condensate return system in a complementary, integrated way and aimed at maximizing the overall efficiency of the system. The integration of these two systems benefits the simultaneous optimization of the flow rate and temperature of the feed water to the generator: the HE-Smart system can work in optimal conditions and distribute the heat recovery on the three exchangers as efficiently as possible.

The steam generator will always work around its optimum point, the stress of the control elements will be less and consequently these organs will be less subject to wear.

The following is an analysis is refered to Cartiera San Giorgio which replaced the steam generator with a modern HE SMART system and the installation of the TESISpL package for low-pressure steam production pressure.