For Tissue, Paper e Corrugators

Boiler

Room

A reliable and performing boiler room is a must in all branches of paper industry.

A reliable and performing boiler room is a must in all branches of paper industry.

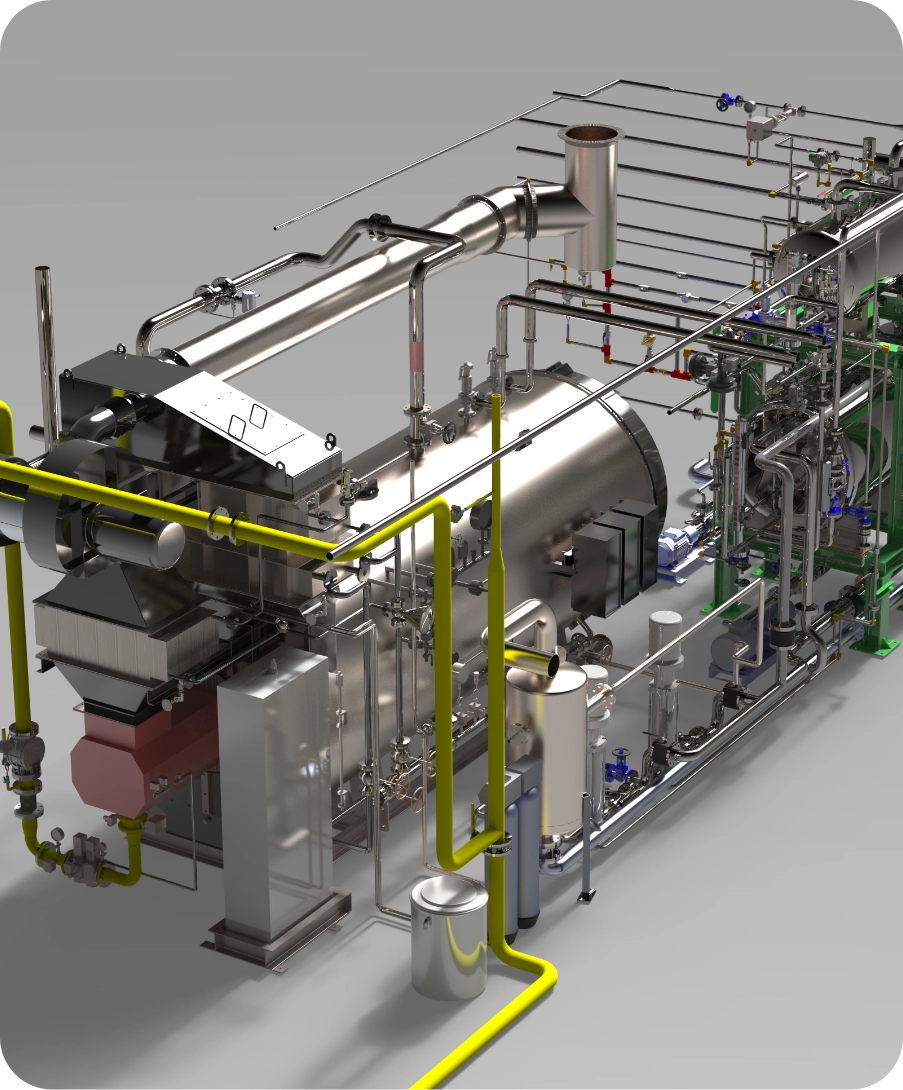

MEVAS provides the entire boiler room, from the sizing during the design stage, through the layout, to the mechanical assembly. Mevas Boiler Room stand out for reliability, components quality, space optimization and constant attention to the energy saving.

TESI is the Mevas system for the condensate managing,created to regulate and empower the operations of the boiler.

Contact Us

TESI, counting on a regularized injection of high-temperature condensate, ensures stable working conditions to the boiler room, increasing its performance with a substantial reduction of gas consumption.

TESI fits perfectly any layout with reduced installation costs, avoiding piping modifications.

TESI installation involves an immediate energy saving ensuring a regular flow of high-temperature condensate to the boiler. The recovery and controlled injection of HT condensate implies less gas consumptions due to the reduced Delta T.

Mevas TESI is equipped with the most advanced controls in order to guarantee to the boiler absolute dependability and stable operating conditions. The constant control of the boiler working conditions is crucial to maximize the steam generation performance and the lifetime of all the components, reducing the overall maintenance costs and knocking down the risk of failures and breakdowns.

The skid structure involves a minimal impact on the existing layout, making TESI perfect for complex installations. Furthermore, TESI can be absolutely integrated to any plant layout, not being necessary substantial piping modifications. Mevas PLC makes TESI indipendent of boiler logics, eliminating adaptation complications and sppeding uop the start-up stage.

Mevas is able to design and realize customized solutions or partial rebuildings for Tissue, paper and Corrugators, in accordance with manufacturing requirements and facility characteristics of the client.

Contact Us

Turn to your paper partner: our team is

always ready to answer promptly your question.

A reliable and performing boiler room is a must in all branches of paper industry.

Read moreIn the Paper industry, an accurate sizing of the Steam & Condensate system and all the main components is fundamental.

Read moreMevas realizes complete high-efficiency drying systems for the paper industry, from the design to the field start-up

Read moreMevas provides high-efficiency dust removal systems for Tissue machines, rewinders and converting

Read moreMevas designs and realises turn-key mist removal systems for the paper industry.

Read moreA well balanced hall ventilation is closely related to the machine characteristics and crucial to avoid manufacturing inefficiencies and structural issues.

Read more