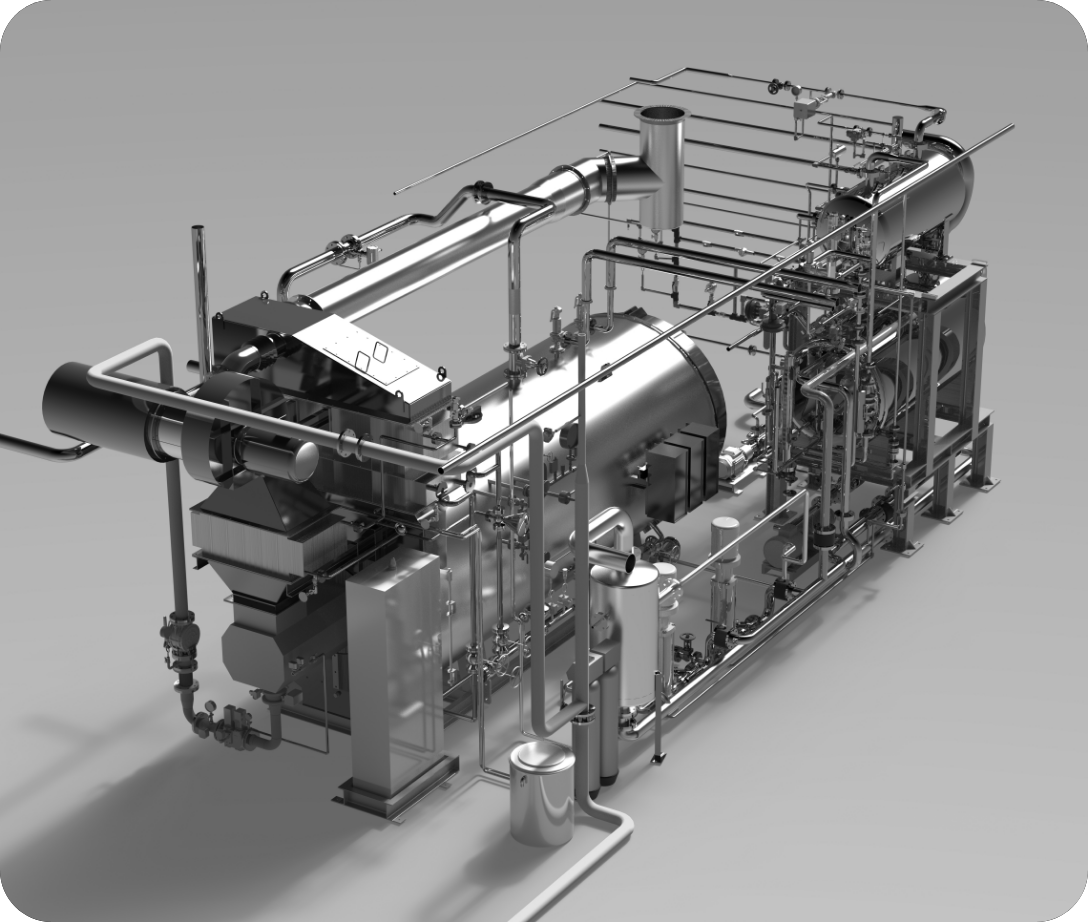

Technologies for the paper industry - Corrugators

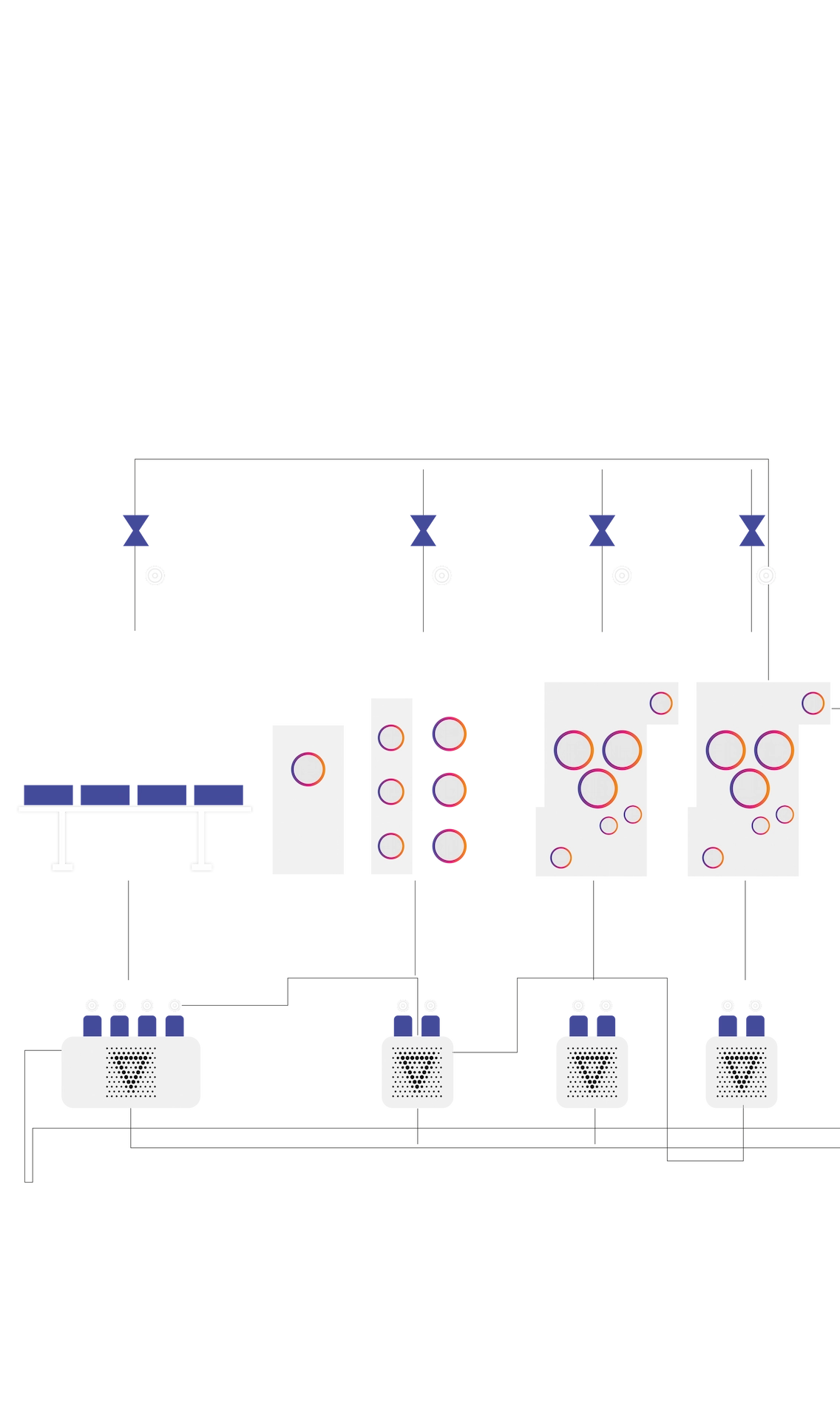

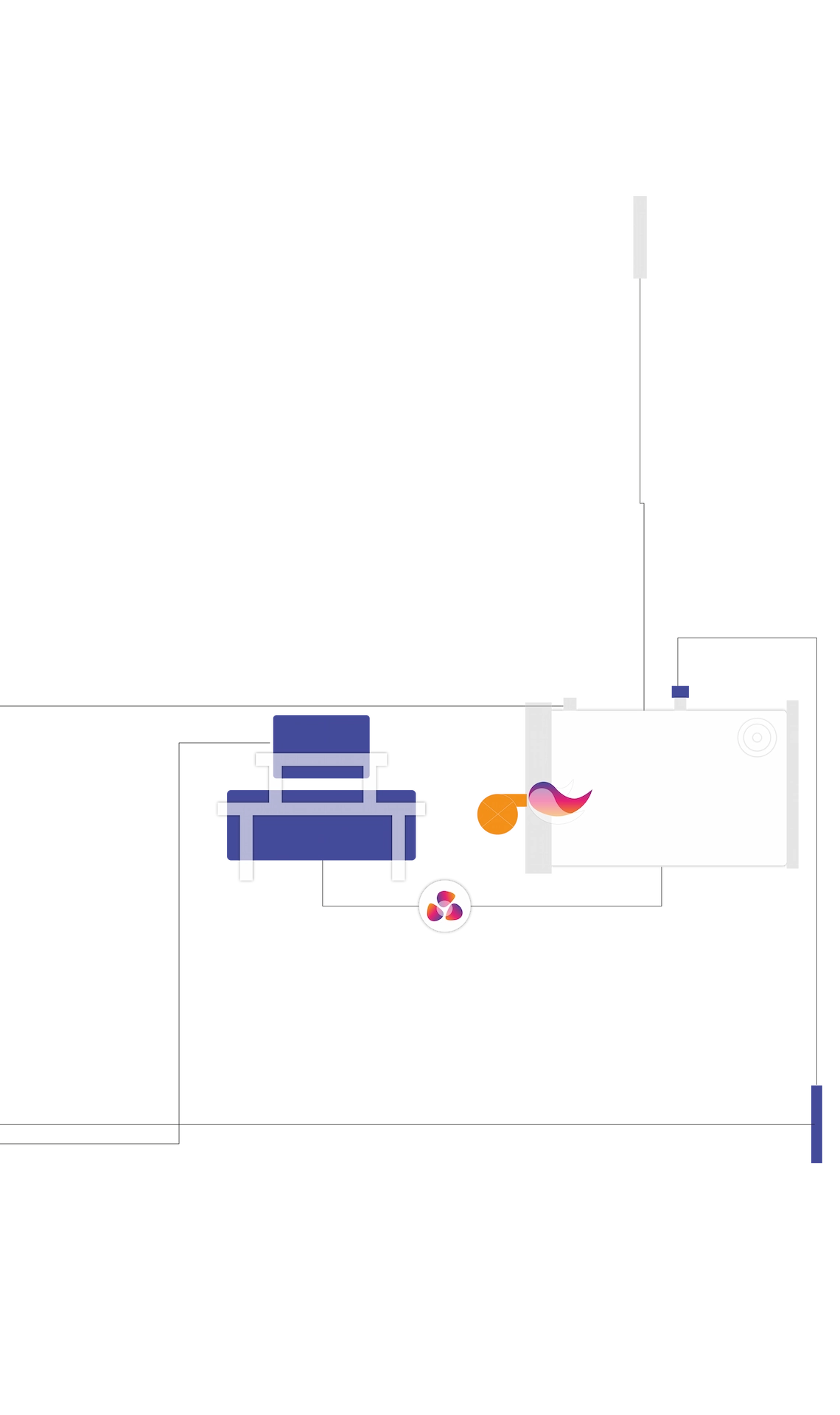

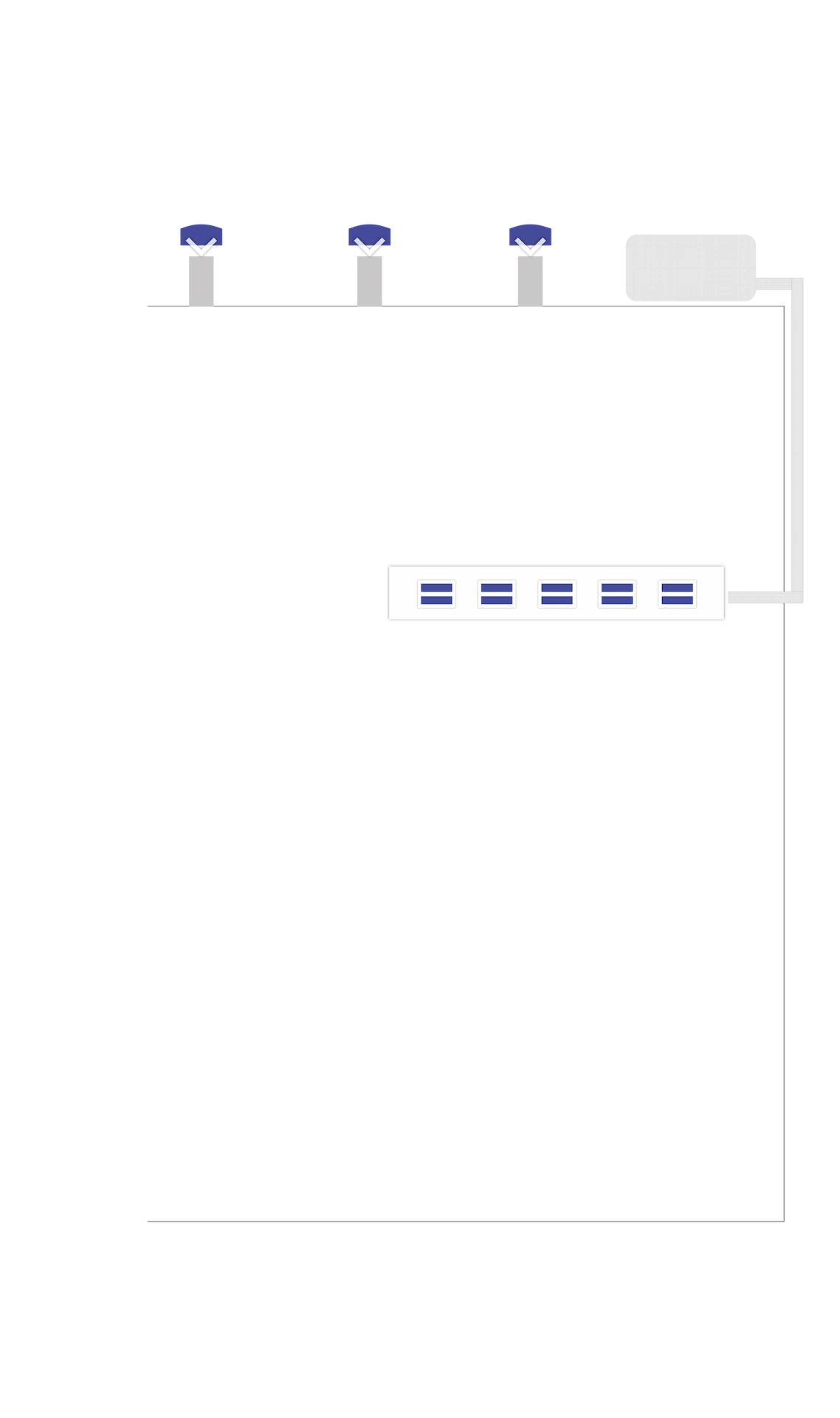

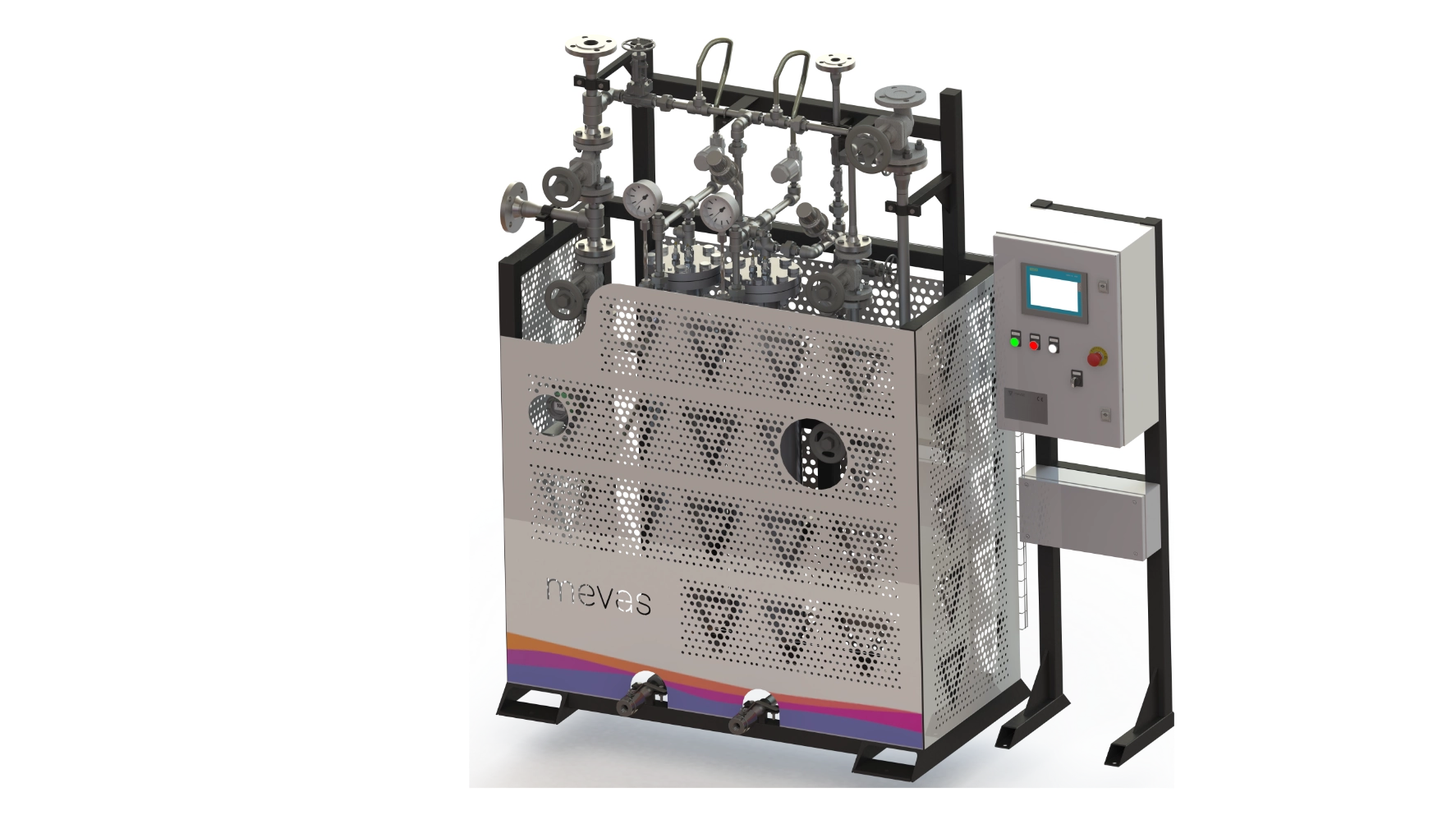

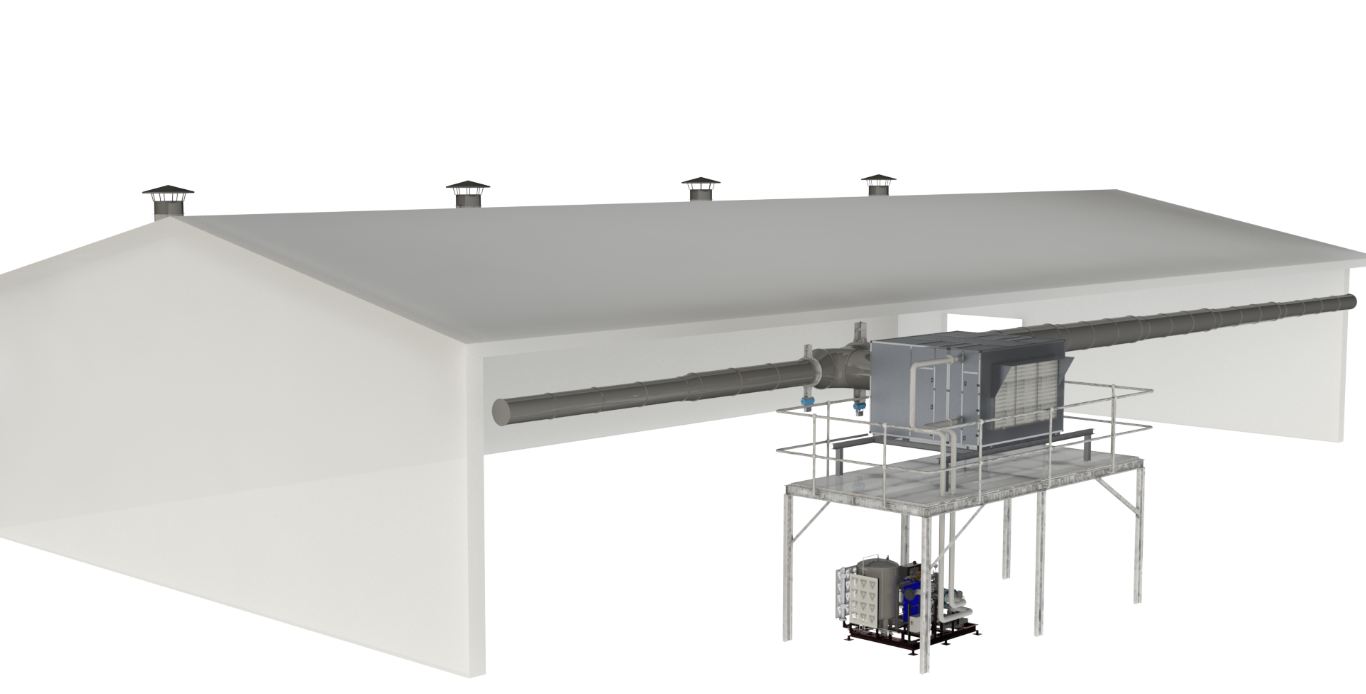

Mevas designes and realizes systems and solutions for the corrugated cardboard industry. The experience gained in Tissue/paper Steam & Condensate systems led Mevas to develop a complete range of products for the corrugators. Mevas corrugators systems are distinguished by an high-tech level and operational reliability.