Per Tissue, Paper e Corrugators

Boiler

Room

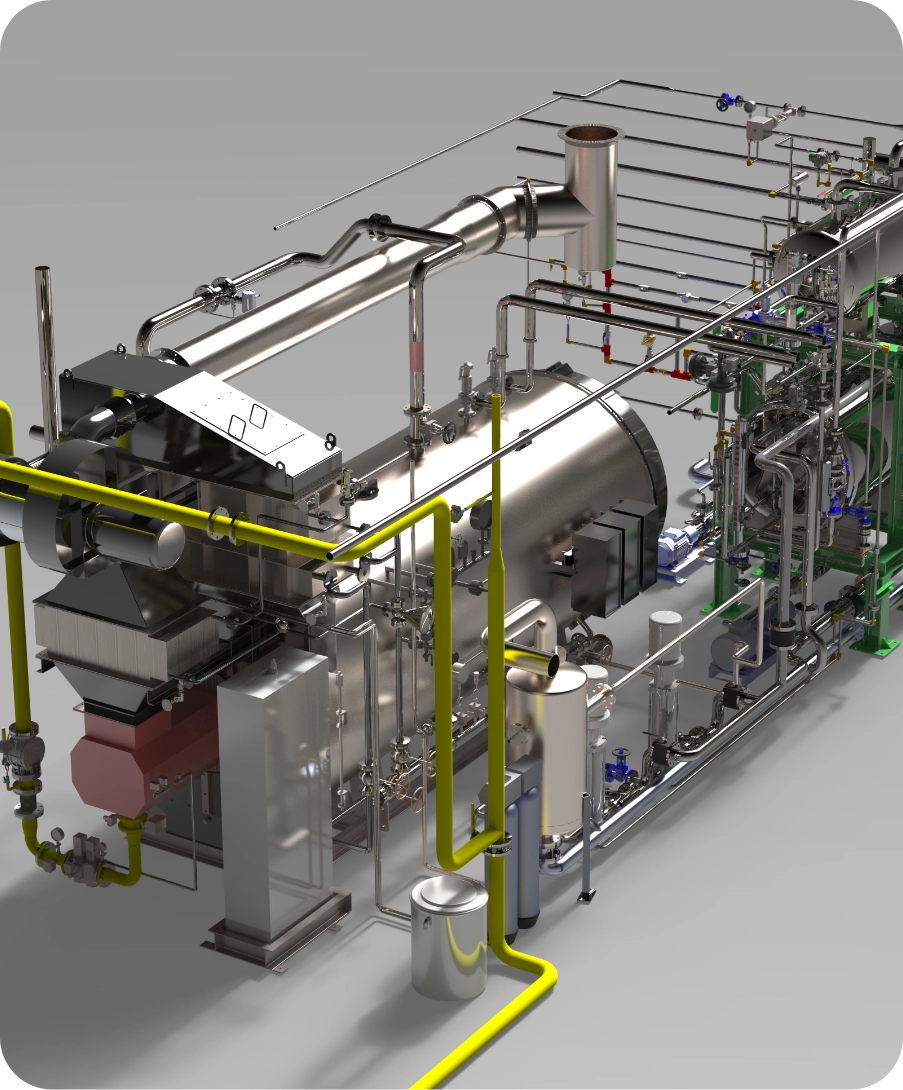

Una Boiler Room performante e affidabile è un must per tutta l'industria cartaria.

Una Boiler Room performante e affidabile è un must per tutta l'industria cartaria.

Mevas è in grado di fornire l’intera Boiler Room, partendo dal dimensionamento in fase progettuale, passando per il layout, fino alla realizzazione dell’impianto. La Boiler Room Mevas si distingue per affidabilità, qualità dei componenti impiegati, ottimizzazione degli spazi e attenzione costante all’energy saving.

TESI è il sistema di gestione delle condense realizzato da Mevas, per

regolarizzare e potenziare il lavoro della caldaia.

TESI, tramite l’iniezione regolarizzata delle condense ad alta temperatura, garantisce alla caldaia condizioni di lavoro stabili, incrementandone la performance e garantendo una riduzione sostanziale del consumo di gas.

TESI si adatta perfettamente a qualsiasi layout senza modifiche sostanziali al piping esistente e con costi di installazione ridotti.

La forza di TESI risiede nel nuovo approccio impiantistico con cui è vista la centrale termica, dove, anche il recupero condense ed il trattamento termofisico dell’acqua di alimento, potranno beneficiare della rapidità di installazione tipica dei sistemi su skid, senza modifiche sostanziali alle tubazioni del processo.Tesi può contare su un sistema automatico di gestione dei transitori, un PLC di sicurezza e il kit per l’assistenza da remoto.

L’installazione di TESI comporta un risparmio energetico immediato dal momento che è in grado di assicurare alla caldaia un flusso costante e regolarizzato di condense ad alta temperatura. Questa iniezione controllata di condense recuperate implica un minor consumo di gas grazie al delta termico ridotto.

Mevas ha dotato TESI dei più avanzati sistemi di controllo in maniera da assicurare estrema affidabilità all’intero sistema e condizioni operative stabili alla caldaia. La regolarizzazione delle condizioni di lavoro implica una massimizzazione della performance nella produzione di vapore e maggior durata nel tempo di tutti i componenti, riducendo i costi di manutenzione complessivi e abbattendo il rischio di guasti e fermo macchina.

La costruzione su skid comporta un bassissimo impatto sui layout esistenti, rendendo TESI ideale per le situazioni impiantistiche complesse. Inoltre, non risultando necessarie modifiche sostanziali al piping esistente, TESI risulta facilmente integrabile a ogni configurazione di stabilimento. Il PLC Mevas, rende TESI indipendente dalle logiche della caldaia, azzerando le complicazioni di interfaccia e velocizzando la fase di start-up.

Mevas è in grado di progettare e realizzare soluzioni personalizzate o

rebuilding per il Paper, Tissue o Corrugators, in totale accordo alle esigenze

produttive e impiantistiche del cliente.

Rivolgiti a un partner esperto nel settore cartario:

il nostro team è pronto a rispondere alle tue

richieste.

Mevas è in grado di fornire l’intera Boiler Room, partendo dal dimensionamento in fase progettuale, passando per il layout, fino alla realizzazione dell’impianto.

Scopri di piùL’impianto Mevas progettato per raggiungere le migliori performance, garantendo affidabilità e continuità di lavoro nel tempo, con il massimo Energy Saving possibile grazie al produttore di vapore brevettato _SP.

Scopri di piùLa perfetta sinergia tra cappa e Air System assieme all’inserimento dei sistemi brevettati Mevas garantisce il raggiungimento dei più elevati standard a livello di consumi energetici ed emissioni.

Scopri di piùL’impianto di aspirazione polveri risulta fondamentale, specialmente nel settore cartario, per diminuire il rischio di incendio, limitare l’usura dei componenti di macchina e soprattutto migliorare la qualità ambientale per gli operatori.

Scopri di piùL’impianto di rimozione delle nebbie di macchina è fondamentale per eliminare umidità e nebbie di formazione, proteggendo le strutture e i componenti di macchina dalla corrosione.

Scopri di piùUn condizionamento sala accuratamente bilanciato in funzione delle caratteristiche di macchina è fondamentale per evitare disservizi e criticità sia a livello infrastrutturale che produttivo.

Scopri di più